The Process of Manufacturing Stainless Steel Explained

Since its beginning in 1872, stainless steel has become an important part of everyday life. American Metal Supply specializes in distributing this metal to Cincinnati and Louisville, OH, area businesses, who can use it for a wide range of purposes. This manufactured alloy has unique resistance to corrosion, which makes it useful in everything from eating utensils to large-scale construction and machines. Stainless steel is manufactured, which means it is man-made rather than found in nature. If you’ve ever wondered how the alloy is created, read on.

The Creation of Stainless Steel

To start, the original iron alloy is placed into a furnace along with enough chromium to make up at least 10.5% of the mixture. Other elements are added as needed, depending on the properties desired in the batch, such as silicon, nickel, carbon, manganese, titanium and nitrogen. It can take up to 12 hours in this furnace for the metal to melt together. The molten mixture is then processed in an Argon Oxygen Decarburization converter, which removes the extra carbon. It is then slowly stirred to improve the consistency of the metal and remove any other extra elements.

To start, the original iron alloy is placed into a furnace along with enough chromium to make up at least 10.5% of the mixture. Other elements are added as needed, depending on the properties desired in the batch, such as silicon, nickel, carbon, manganese, titanium and nitrogen. It can take up to 12 hours in this furnace for the metal to melt together. The molten mixture is then processed in an Argon Oxygen Decarburization converter, which removes the extra carbon. It is then slowly stirred to improve the consistency of the metal and remove any other extra elements.

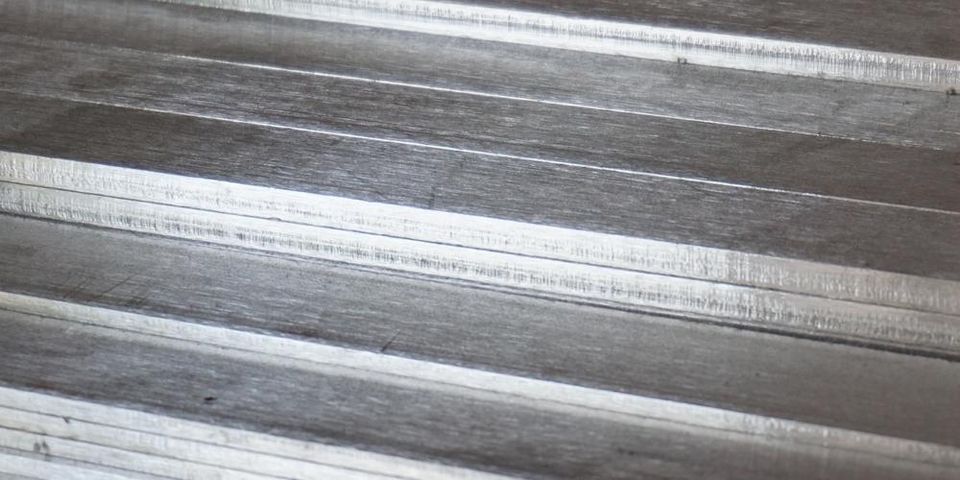

Next, the metal is cast into forms, such as rectangles or tubes, and is passed between a series of rolls, a process which is called rolling. Rolling can be done in hot or cold conditions; the temperature at which this is done will determine the grade of the steel. For example, cold rolling often results in an attractive finish.

The next step is annealing, in which the steel is alternately heated and cooled to improve the ductility and softness. This change in temperature can result in a scale buildup on the metal, which needs to be removed. After the cold finished steel is cut and given the desired finish, it’s ready for use.

When you need stainless steel or other top-quality metals, call American Metal Supply at either their Louisville branch at (502) 634-4321 or their Cincinnati branch at (513) 396-6600 to request a delivery. They offer service around the clock and strive to exceed your expectations. You can also visit their new website for details on their products and metal processing solutions.

About the Business

Have a question? Ask the experts!

Send your question