3 Sheet Metal Fabrication Techniques

Metal processing is crucial for construction, toolmaking, and car creation, along with a long list of other applications. However, a lot happens to a piece of metal from the point it is molded into a sheet, bar, or tube and when it’s handed over to a fabrication team. Here are three fabrication techniques that metal processing companies may use.

How Metal Is Fabricated

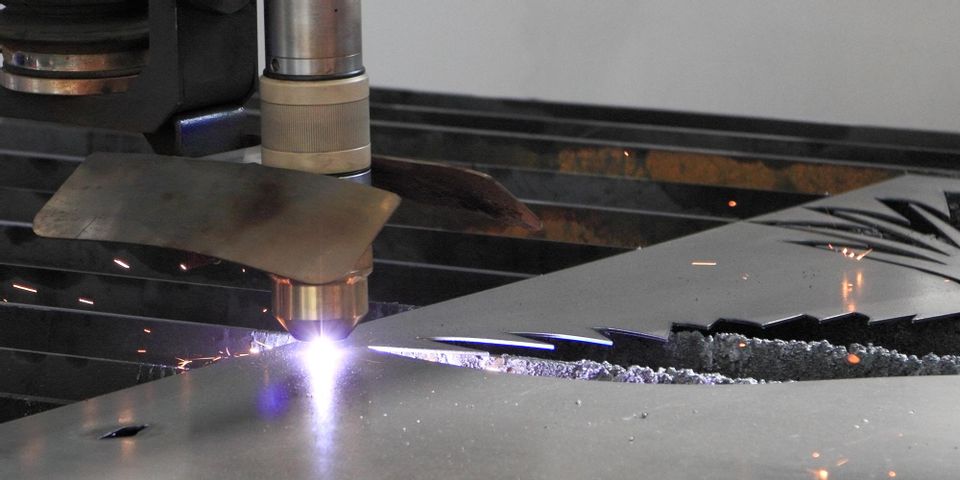

1. Cutting

Before metal can be used to create brackets, car doors, or structural frameworks, it may need to be cut. In addition to using high-power hydraulic cutters, modern metal processing uses lasers and computer-guided CNC machines to create intricate designs in the metal. Laser cutting tools may be used to make large metal signs, logos, or even custom construction pieces for buildings.

2. Bending

While the blacksmiths of yesteryear used hammers and anvils, modern metal processing teams use large devices called metal brakes to bend sheets of metal. These presses are operated by the user and can be designed to create straight bends in the metal. Press brakes are typically used to create stark angles in metal, such as 90-degree angles to fit brackets over a corner.

While the blacksmiths of yesteryear used hammers and anvils, modern metal processing teams use large devices called metal brakes to bend sheets of metal. These presses are operated by the user and can be designed to create straight bends in the metal. Press brakes are typically used to create stark angles in metal, such as 90-degree angles to fit brackets over a corner.

3. Hemming

Metal is stronger when it is folded over onto itself, which is why many metal edges are hemmed. During hemming, a metal brake bends the edge of a metal sheet over onto itself, and then a roller presses the metal together to create a smooth, sturdy edge. During hemming, professionals can also create a rounded hemmed edge called a barrel edge.

If you are interested in metal processing and you need a new metal supplier, contact American Metal Supply in Louisville, KY, and Cincinnati, OH. This trusted supplier offers everything from galvanized steel and aluminum to stainless steel and plastics. To find out more about how they can help you, visit their website or call (502) 634-4321.

About the Business

Have a question? Ask the experts!

Send your question