A horizontal boring mill, also known as a horizontal boring machine, is a useful and versatile tool in machining equipment or parts. It is unique because it enlarges holes horizontally rather than vertically. If you’re using one for a project of yours, then you may want to learn more about what these machines are and the value they can provide for your business.

What to Know about Horizontal Boring Machines

What They’re Used For

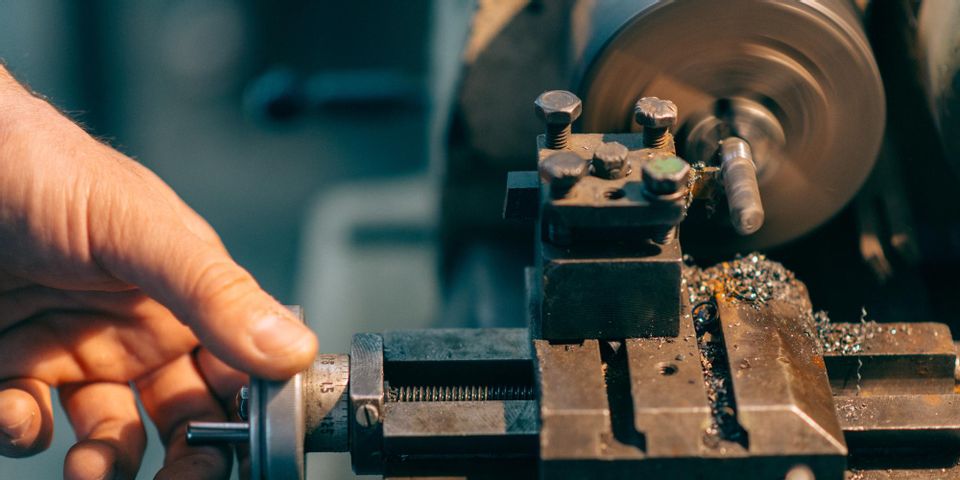

Boring is the process of enlarging an existing hole to a precise size. These machines can also taper the diameter of the hole. A boring mill can handle anything from rough machining for heavy-duty large components to precision grinding for something such as perfecting intricate gears.

The more precise work is controlled with a pre-programmed computerized system to avoid the issue of human error. This type of work creates machinery and parts that are used in a wide range of industries, from automotive engines to aerospace engineering.

How They Work

A horizontal boring mill has its work spindle parallel to the floor so that it can bore horizontally. The three main types of these machines are the table, planer, and floor mills. The table type is the most common since it allows the work to be secured on a table and uses attachments to perform more than just boring for versatility.

A horizontal boring mill has its work spindle parallel to the floor so that it can bore horizontally. The three main types of these machines are the table, planer, and floor mills. The table type is the most common since it allows the work to be secured on a table and uses attachments to perform more than just boring for versatility.

These job functions include but are not limited to threading, facing, reaming, grooving and recessing. The floor type secures the work to the floor with t-slots and is best for large or heavy workpieces. The planer type uses a sliding table, which is best for long work.

The R. A. Heller Co. machine shop team has served the Cincinnati area with high-quality engineering since 1946. They use cutting-edge equipment such as a horizontal boring mill for efficient manufacturing at affordable prices. In addition to saving you money, they are dedicated to eco-friendly practices, so you can trust that working with them will benefit the environment. Contact them online or at (513) 771-6100 to discuss your project today.

About the Business

Have a question? Ask the experts!

Send your question