Precision grinding is a process that has numerous applications within many industries. It’s often used during the manufacturing process, while also benefiting the toolmaking industry thanks to how precise and accurate dimensions can be. The following are a few key components of the grinding process so you can make the best decisions to fit your needs.

Through-Feed vs. In-Feed

Both through-feed and in-feed are types of centerless grinding. However, there are a few notable differences between these two feed types. With through-feeding, the part goes directly through the machine during the grinding process. In some cases, continuous grinding is possible, which is ideal for high-volume projects.

With in-feed grinding, parts must be loaded manually into the machine, which is good for parts that are odd sizes and more difficult to cut. The part must be passed through the machine manually, which provides greater control over intricate cuts.

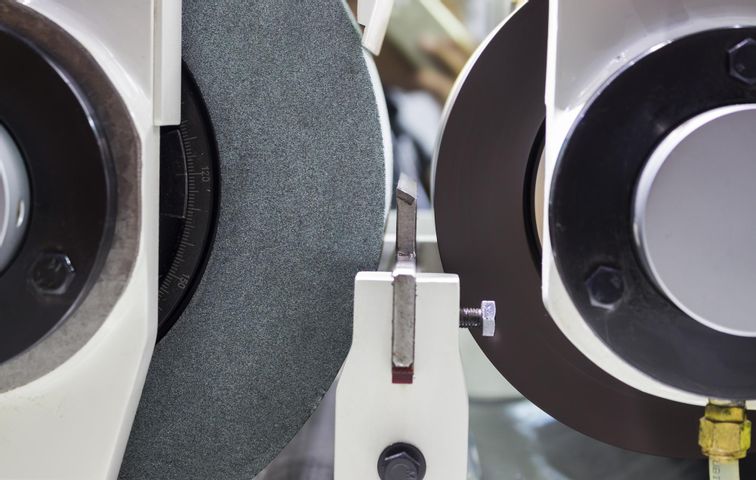

Choosing the Right Grinding Wheel

T he grinding wheel you use will have a significant impact on the quality of the end product. While you can work with your machine shop to make the best choice, ensure the wheel you choose is best suited for your project. Some wheels may create too much stress on parts or generate a lot of heat, both of which can warp components.

he grinding wheel you use will have a significant impact on the quality of the end product. While you can work with your machine shop to make the best choice, ensure the wheel you choose is best suited for your project. Some wheels may create too much stress on parts or generate a lot of heat, both of which can warp components.

You must make sure that the wheel is balanced correctly while being used. A well-balanced wheel allows for the best precision grinding, and you’ll achieve the exact shape you’re going after. Conversely, when wheels are off-balance, the surface of the item you’re grinding won’t be completely round. Wheel balance should be checked frequently for the best outcome.

As a trusted Cincinnati machine shop, R. A. Heller Co. will help you make the best decisions when it comes to your precision grinding needs. With more than seven decades of experience, they’re equipped to serve numerous industries, including roofing, mills, paper plants, and many others. Their 20,000-square-foot facility is equipped to handle jobs large and small. Call (513) 771-6100 for more information or visit their website to learn more about their services.

About the Business

Have a question? Ask the experts!

Send your question