3 Advantages of Bucket Elevators

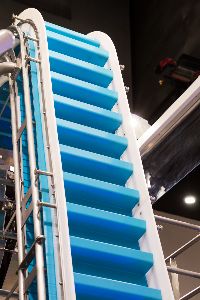

When thinking about material handling and conveying, most people immediately jump to equipment that moves items horizontally. For example, products might travel through a trough and screw or a belt, before being packaged. However, vertical movement is essential at many work sites for moving materials to another height, or when limited floor space dictates. KWS conveying, www.kwsmfg.com manufacturers excellent quality and high efficiency bucket elevators to lift materials using large buckets attached to a rotating chain or belt. Often, these are raw ingredients, such as sugar, iron, or grain. From there, these items can go through the next stage of processing. The following guide explains the advantages of bucket elevators.

Why Your Company Should Use Bucket Elevators

1. Protective

Bucket elevators are often fully enclosed. Once materials are added, they don't come in contact with outside debris. This prevents damage to the products or supplies and ensures they remain as effective as possible. For instance, agriculture companies moving fertilizer can prevent moisture from contaminating it before it’s applied. This concept is especially important when dealing with food-grade products like animal feed.

2. Durable

Bucket elevators are made using strong materials like carbon steel and poly carbonate that last a long time in service. This reduces the risk of wear over time as products travel through the system and rub against the walls. If necessary, metals can be treated with moisture-resistant coatings, or made with food grade materials, which allows you to complete jobs without worrying about corrosion, contamination or water damage to the equipment.

3. Efficient

Bucket elevators require less floor space, can handle materials like mulch, aggregates, and even delicate minerals, better and faster than horizontal conveyors in many applications. Automating frees up your time and space to focus on other areas of your operations while still ensuring that your materials are carefully moved to the next stage of processing.

If you’re ready to reap the benefits of bucket elevators, turn to Industrial Component Sales. The company has locations in Hudson, WI, Bemidji, MN, Delavan, WI, and Lincoln, NE, helping clients in various industries find the material handling and conveying solutions that work best for their needs. Visit the website to see a full selection of their offerings. To speak with a representative about your material handling and conveying needs, call John at (651) 270-0151.

About the Business

Have a question? Ask the experts!

Send your question