What Is the Difference Between a ‘Clean Room’ & a ‘White Room’ for a Manufacturing Company?

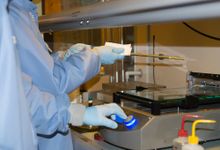

A manufacturing company, regardless of what it produces, has to maintain a highly controlled environment that is free from any contaminants to ensure maximum product integrity. That’s why most reputable companies either have a “white room” or a “clean room.” In simple terms, a white room has all the same features as a clean room but goes a step beyond by eliminating all signs of contaminants in a properly segregated and pressurized environment. Below is a closer look at what each is and how they differ.

What Is a Clean Room?

A clean room is often used in fields that make products with high sensitivity to environmental contamination, such as in the pharmaceutical and aerospace industries. While it follows strict protocols to limit the existence of contaminants in the area, a clean room can only control the levels of airborne particles present in the production line, but not eliminate them.

What Is a White Room?

A white room is another type of controlled environment typically used for the production of precision mechanisms and medical devices. It features more sophisticated amenities compared to a clean room and is well segregated to ensure that all aspects of production are done in an environment with zero pollution. White rooms make it possible for a manufacturing company to carry out production without running the risk of cross contamination from any type of pathogenic agents.

A white room is another type of controlled environment typically used for the production of precision mechanisms and medical devices. It features more sophisticated amenities compared to a clean room and is well segregated to ensure that all aspects of production are done in an environment with zero pollution. White rooms make it possible for a manufacturing company to carry out production without running the risk of cross contamination from any type of pathogenic agents.

Regarding contamination control, white rooms are preferred to clean rooms. However, they also require a more significant investment. If you need assistance choosing the right controlled environment for your product, contact Pacific Integrated Manufacturing at (760) 822-3341. This manufacturing company based in Bonita, CA, has over 15 years of experience in providing superior assembly services for various industries. You can also visit their website for an overview of their services.

About the Business

Have a question? Ask the experts!

Send your question