4 Benefits of Plastic Medical Device Manufacturing During COVID-19

During COVID-19, the importance of personal protective equipment (PPE) and medical supplies has never been greater. As a result, the plastics industry has seen an increase in their demands, providing key medical device manufacturing services to support the health care industry. Here is an overview of how plastics have been used in the pandemic and what benefits they offer.

4 Ways Plastic Medical Device Manufacturing Is Crucial in the Pandemic

1. Rapid Production

Toward the beginning of the pandemic, PPE and medical supplies were being used faster than they were being made, causing a scarcity. Plastic manufacturing companies adopted non-traditional solutions to meet the increased demands, such as offering increased wages for workers to quarantine away from home and continue critical medical device manufacturing. Some manufacturers were able to double their output of plastics for respirators, ventilators, and PPE, providing invaluable support when supplies were dwindling.

2. Single-Use Products

Plastics create effective single-use medical devices and PPE. Since they can be thrown away immediately, germs are less likely to spread around, and a fresh device can be used the next time it’s needed.

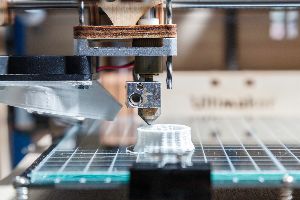

3. 3D Printed Parts

Plastics have also filled the needs for medical device parts, such as valves for respiratory machines. They're created through 3D printing, which produces critical parts at significantly lower costs than manufacturer part replacements. 3D printing can create virtually any part as long as the plastics and the blueprint are available, which prevents shortages that can threaten lives.

4. Antibacterial Innovations

Plastics have driven advancements in killing bacteria. Specially formulated copper blends—oxidized copper mixed with plastics—neutralize viruses like polio and HIV and reduce illness transmission when used on surfaces and linens in health care settings. Now, they’re being tested for efficacy in equipment like face masks to neutralize COVID-19, which could greatly reduce transmission.

If you need reliable medical device manufacturing, contact Pacific Integrated Manufacturing in Bonita, CA. For over 20 years, they’ve provided quality manufacturing in an expansive facility, with services including plastic molding, custom automation solutions, and packaging and logistics services. Products are sterile and can be produced in batches of any size, with tracking, barcoding, and pad printing available. Explore their facilities online, and call (619) 921-3464 for a quote.

About the Business

Have a question? Ask the experts!

Send your question