3 Types of Plastic Used for Medical Manufacturing

Manufacturing equipment for the medicine or science industry relies heavily on plastic injection molding. This process requires the right medical-grade plastic to shape and form a material properly, but it can be difficult to determine which one best suits your needs. Make the selection process easier by reviewing some of the most popular options in the guide below.

What Plastics Are Often Used for Medical Devices?

1. Acrylonitrile Butadiene Styrene (ABS)

This thermoplastic polymer is an excellent metal substitute for structural parts. That's because it's heat-resistant, abrasion-resistant, and chemical-resistant and features anti-corrosive properties, too. It's also frequently utilized to manufacture tracheal tubes, non-absorbable sutures, tendon prostheses, and drug-delivery systems.

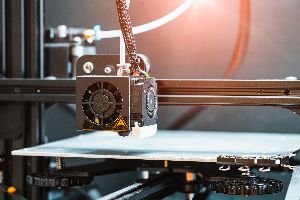

Commonly used for 3D-print manufacturing for medical devices, this plastic is created by polymerizing styrene and acrylonitrile in polybutadiene. Additionally, it can be injected, blow-molded, extruded, melted, or reshaped.

2. Polycarbonate

Polycarbonate is a thermoplastic polymer with excellent ultraviolet (UV) protection properties. This strong polymer is created by condensing bisphenol A and phosgene. Its transparency makes this plastic injection molding a good alternative for glass in medical devices.

This polymer is known for its shatter and heat resistance, high strength, and biocompatibility. Additionally, it can withstand multiple sterilization methods like steam, gamma radiation, and ethylene oxide (EO).

3. Polystyrene

Polystyrene is a hard, stiff synthetic resin. This transparent polymer is made from monomer styrene, a liquid hydrocarbon. Commercially manufactured from petroleum, this thermoplastic can be solid or foamed, depending on the temperature it gets exposed to. In the medical industry, it's commonly used for devices like test tubes and Petri dishes.

For dependable plastic injection molding services, rely on Pacific Integrated Manufacturing. Based in Bonita, CA, they have offered quality and cost-effective solutions for over 20 years. Their 50,000-square-foot manufacturing plant boasts state-of-the-art rooms, including inspection and testing for plastic injection molding. These technicians provide complete contract manufacturing services, including assembly kitting, packaging, material procurement, thermoplastics, and sterilization management. Call (619) 921-3464 for a free quote, and learn more about their services online.

About the Business

Have a question? Ask the experts!

Send your question