3 Tips for Effective Plastic Injection Molding

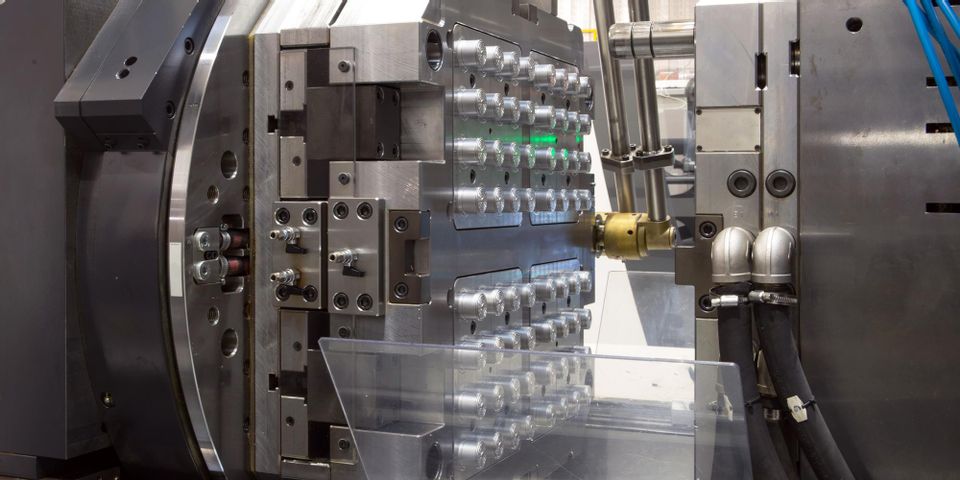

Plastic injection molding allows manufacturers to produce bulk parts for industries including life sciences, medical devices, and diagnostics. Using modern technology and techniques, these producers work hard to keep costs down while creating high-quality goods. Here’s how best to design the molds to that end.

Plastic Injection Molding Essentials

1. Use Thinner Wall Sizes to Avoid Shrinking

A product may warp due to shrinkage while it cools. The issue can ruin a piece, wasting finances and requiring an item redesign, which delays production schedules. To avoid the problem, ensure the size of the walls are thinner and uniform, rather than varying in thickness. Thin walls allow the item to cool more easily.

2. Opt for Curves Rather Than Corners

Sharp angles on a product create a stress point that may buckle with enough applied pressure. Instead, design a product with gentler curves and smooth surfaces. Doing so reduces the risks of warping, damage to the product during use, and inordinate wear.

Sharp angles on a product create a stress point that may buckle with enough applied pressure. Instead, design a product with gentler curves and smooth surfaces. Doing so reduces the risks of warping, damage to the product during use, and inordinate wear.

3. Keep Designs Simple

As with many types of production, simpler designs are often better. The more complex a piece is, the more opportunities there are for something to go wrong. During the planning stage, edit as many unnecessary features and facets as possible, while still ensuring the time will perform its function effectively.

Do you need assistance with plastic injection molding, medical device manufacturing, or assembly packaging? Turn to the team at Pacific Integrated Manufacturing in San Diego, CA. For over 15 years, they’ve provided quality services to clients in the medical industries, offering innovative methods to keep costs manageable. Their 50,000 square foot plant is fully equipped to handle large, involved projects on reliable schedules. Learn more about the services they provide by visiting them online. To speak with a representative today about your needs, call (760)822-3341.

About the Business

Have a question? Ask the experts!

Send your question