An Introduction to Clamp Force

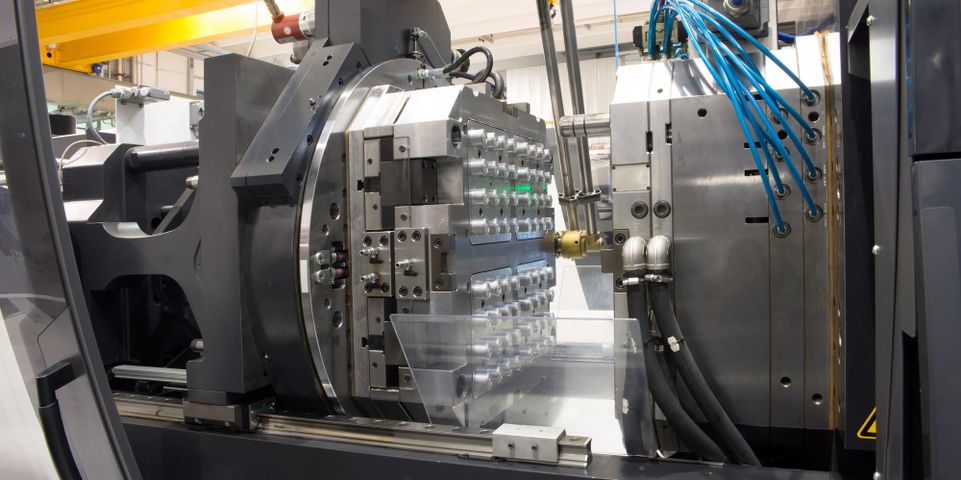

The precision of plastic injection molding is dependent on many factors, including clamp force. Rather than running the machine at maximum clamp force at all times, calculating and setting it properly is essential to achieving optimal quality molds. The following guide breaks down what you need to know about clamp force.

What Is Clamp Force?

Clamp force measures the clamp tonnage the molding machine is capable of expending. The measurement must match the pressure needed to hold the mold closed during the injection process. Every part will require a different clamp force, so it’s highly recommended to set the machine for each to avoid damaging the mold.

How Does It Affect the Injection Molding Process?

In plastic injection molding, proper clamp force is necessary for cost efficiency, high-volume production, and better-quality products. If clamp force is not optimized, you run the risk of producing defects and even throwing off part dimensions.

In plastic injection molding, proper clamp force is necessary for cost efficiency, high-volume production, and better-quality products. If clamp force is not optimized, you run the risk of producing defects and even throwing off part dimensions.

If it’s not set high enough, the injection pressure could force open the mold too early and create a thin residue of waste plastic on the part, rendering it unusable. Set the clamp tonnage too high, and you may end up with damaged parting lines, blocked vents, and warped platens.

How Is Clamp Force Calculated?

Since clamp force will determine the capacity of the machine, it’s usually the first factor calculated. To find out the correct pressure needed, an injection molding engineer will use a formula that includes the total projected area of the part, the average wall thickness of the part, the number of cavities in the mold, and the flow length—or the distance from the edge of the part to the gate of the mold. They may also factor in the material supplier’s recommended clamp force.

While these calculations can be done by hand, today’s plastic molding programs can do the work themselves.

For precise, high-quality plastic injection molding, turn to Pacific Integrated Manufacturing of Bonita, CA. Since 2000, the company has provided life science, diagnostic, and medical device manufacturing, including services like assembly kitting, packaging, and precision custom injection molding. With an impressive 50,000-square-foot plant, they mass-produce top-quality products and pass the savings on to clients. For more information about their plastic injection molding services, visit their website. Call (619) 921-3464 today to receive a free quote.

About the Business

Have a question? Ask the experts!

Send your question