When designing cleanrooms for research or different industries, there are many factors to consider. A cleanroom should be devoid of all dust and contaminants and meet the classification required by your industry or application. The following are answers to common cleanroom FAQ, provided by Midwest Medical Systems, in Dayton, OH.

Common FAQ for Cleanrooms

How Does a Cleanroom Work?

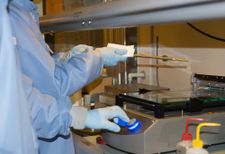

A cleanroom acts as a controlled environment that is free of dust or contaminating particles. Cleanrooms are used for the manufacture of electronics, for scientific research, and in the aerospace, optics, pharmaceutical, and nanotechnology fields. They require personnel to wear specialized clothing such as gowns, bodysuits, booties, and hoods to keep human contaminants to the absolute minimum. Most cleanrooms operate in a positive pressure method. Three-stage filtered air flows into the room and is forced out through vents in the floor. Particles are removed with the air. Less common are negative pressure rooms that are meant to contain hazardous substances. Air is pulled from other rooms, then flows out, is filtered, and released.

How Are Cleanrooms Built?

They are built with non-particulating products for the ceiling, walls, floor, and any mechanical systems they contain. HVAC equipment is designed using non-shedding products and advanced filtration of both inside and outside air. Airlocks and special dressing areas provide an entrance for cleanroom workers. At every step of the construction process, the area must be cleaned.

They are built with non-particulating products for the ceiling, walls, floor, and any mechanical systems they contain. HVAC equipment is designed using non-shedding products and advanced filtration of both inside and outside air. Airlocks and special dressing areas provide an entrance for cleanroom workers. At every step of the construction process, the area must be cleaned.

How Are Cleanrooms Classified?

Cleanrooms are classified by the International Standards Organization (ISO). Classes are defined by the maximum number of particles allowed per cubic meter of air. Cleanliness classifications go from 1 (cleanest) to 9. Cleanrooms have three states, as built, at rest, and operational. The cleanliness certification is based on the as built state, which is the completed room before any equipment or people have been in it. The classification you need depends on your industry. Keep in mind that the number of particulates in the air in an as built room will increase once you are in the operational stage.

Building the right cleanroom for your needs and industry standards is essential. The professionals at Midwest Medical Systems design cleanrooms, and can provide information on clinical refrigeration systems, barrier isolators, mobile computing carts, and other pharmacy solutions. Contact us today at 937-424-0241 or email melanie@midwestmedical.us

About the Business

Have a question? Ask the experts!

Send your question