Electric motors are sophisticated pieces of machinery. However, failing to maintain a motor or address operational issues can lead to more serious damage and decrease the usability and life span of the device. For these reasons, electric motor repairs should be a priority at the first of a problem. Below, learn about a few common signs of electric motor malfunctions, as well as some ways a professional can repair them.

What Are Signs of a Failing Electric Motor?

The most obvious indicator of electric motor failure is worsening performance. This is often caused by issues with the mounting or by inadequate lubrication. The motor won't run as efficiently, so it may run noticeably slower or have trouble starting or maintaining power.

Overheating is another red flag to watch out for. This is usually the result of contamination, a lack of ventilation around the device, or reliance on the wrong voltage supply. Overheating can make the motor burn out and stop working altogether.

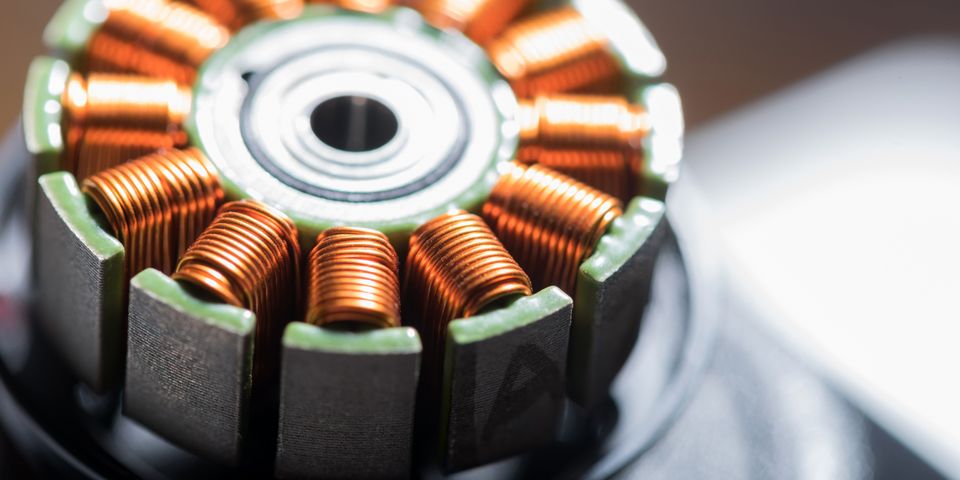

Winding failures are also common among electric motors. This issue can stem from bad electrical connections, thermal deterioration of insulation, or a loose motor shaft or bearing. Winding problems will often render a motor unusable, which can affect the efficiency of its performance.

What Are Repair Options?

The first step in electric motor repair is to inspect the device and identify the cause of the issue. Then, the provider will remove any damaged windings and clean the motor and insulation. A thorough cleaning will help you avoid damage in the future.

The provider might paint the stator with special insulating paint and line the stator slots with insulation. This will minimize the risk of shorts and also help prevent future damage.

If new coils are needed, the provider will create replicas of the originals and install them in the stator slots. Then, they will add additional insulation to safeguard the new coils. This is followed by a testing of the coils and a confirmation that the repair has been successful.

Finally, the motor is dried, coated, and cured. This process removes any remaining contaminants and provides one last layer of protective coating.

When you need electric motor repairs in the Greater Cincinnati Tri-State Area, contact A-1 Electric Motor Service. Since 1961, they have been a trusted source of electric machining services. From rewinding and pump repair to welding and balancing, they are here to preserve the operation and longevity of the equipment you rely on. Call (859) 291-1351 or visit them online to request an estimate.

About the Business

Have a question? Ask the experts!

Send your question