What is Electroplating & Why Do Jewelry Manufacturers Use It?

When you see someone wearing an eye-catching piece of jewelry, you may not consider all of the many steps that went into making the design completely flawless. One such step is electroplating, a common finishing practice jewelry manufacturers use to enhance certain types of metals and alloys. The experienced and talented team from Frank Billanti Jewelry Casting Co. in New York City, NY, sheds some light on the electroplating process.

What Is Electroplating & Why Is It Used by Jewelry Manufacturers?

What Is It?

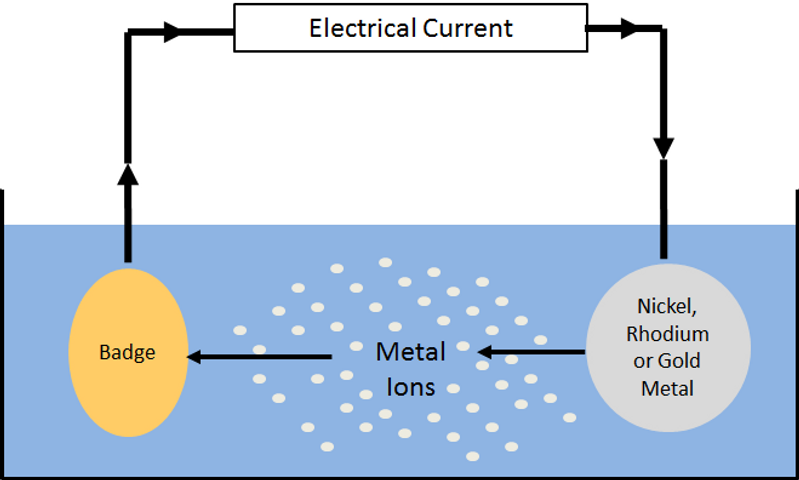

Electroplating is the process of applying a metal coating on an object. When used in the jewelry process, it can enhance the aesthetic value and wearability of a piece. Before electroplating begins, a jeweler may strip, hand polish, or sandblast the jewelry to prepare its surface. The piece is then ultrasonic cleaned and electro-cleaned to remove oils and dirt. Finally, a deep steam cleaning is performed to remove any lingering oils and dry the piece.

Next, the piece is rinsed once again, and in some cases, a thin layer of palladium plating (also called the strike layer) is applied to the jewelry. This can achieve a stronger bond between the plating and the original surface. The piece will be rinsed once again before receiving the final coating of metal (gold, rose gold, rhodium, or silver).

Why Is It Done?

Electroplating can enhance the appearance of jewelry in a number of ways. A piece of gold jewelry might be electroplated with 24-karat gold to achieve a richer hue. In fact, a range of color options can be achieved through the electroplating process. For instance, Frank Billanti Casting offers 10K, 14K, 18K, and 24K gold plating. Rhodium electroplating can enhance the whiteness of white gold.

What Are Some Other Reasons It’s Used?

Electroplating can increase the appearance of color uniformity in jewelry. The process usually improves tarnish resistance, meaning your jewelry will stay polished and beautiful for a longer period of time. It may also be used on base metal or silver items to achieve a real gold appearance.

The expert team of jewelry manufacturers at Frank Billanti Jewelry Casting Co. provides a broad range of jewelry casting, finishing, setting, and electro-plating services. To discuss your needs with one of their professionals, call (212) 221-0440. You can also visit the company’s website to learn more about their services.

About the Business

Have a question? Ask the experts!

Send your question