How Is Polyurethane Utilized in the Automotive Industry?

5 Ways Polyurethane Is Used in the Automotive Industry

Polyurethane is a plastic polymer that’s used in a wide variety of industrial and consumer products, including car parts, mattresses, shoe soles, and a variety of medical applications. Polyurethanes are superior to other materials in tear resistance, flexibility, and abrasion resistance.

Polyurethanes are used in the making of many Automotive parts in the market today. Polyurethanes come in many forms; from rigid clear and hi-temp resins, to foams and adhesives. The automotive industry uses thermoset polyurethanes for prototypes and initial parts because of its excellent durability, corrosion resistance, reduced weight, and heat & ultraviolet resistance. Here are some ways polyurethane is used in the Automotive industry.

1. Air Intake Systems: Many Polyurethanes are tough enough for use in high-heat, under-hood applications. A good air intake system allows for clean and continuous airflow into the engine, thereby achieving more power and better mileage for cars. The smooth interior of a Roto-casted heat and impact resistant polyurethane helps boost the air flow performance of the intake tube system.

2. Auto Lenses: Water Clear polyurethanes exhibit exceptional clarity for the creation of auto lenses. Rigid clear casting resins have been designed for use in applications requiring tough & tintable materials that will also survive outdoor applications due to UV exposure.

3. Hood Ornaments: Rigid casting polyurethanes are formulated to simulate a wide array of thermoplastic products such as polypropylene, ABS, and Polycarbonate. For Prototyping and production, polyurethanes are an ideal material choice for casting hood ornaments.

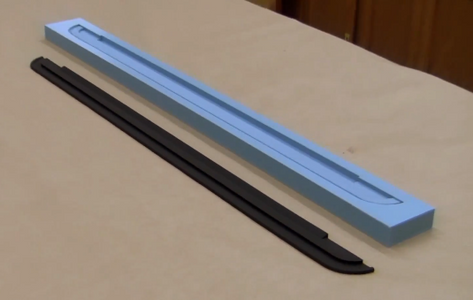

4. Rubber Trim: Polyurethane elastomers produce extremely durable automotive gaskets, seals, & trim. The ease of molding these materials, combined with polyurethane’s strength, and durability make them ideal for use in the automotive industry.

5. Seat Cushions: Polyurethane foams are used to create long lasting automotive seat cushions. Even under heavy use, polyurethane foam retains its original firmness, shape and resiliency. Arm rests, head rests, seat cushions are all made with polyurethane foams.

If you’re looking for molds and casting supplies, turn to the professionals at BJB Enterprises in Tustin, CA. They have been in business since 1970 and offer polyurethane, silicone, and epoxy products. These professionals work with several industrial companies to manufacture unique and customized products, using 3D printing to make precise molds and castings. They’re ISO certified and go beyond the call of duty to provide their customers with quality products. For more information about their custom products, call (714) 734-8450 or visit their website.

About the Business

Have a question? Ask the experts!

Send your question