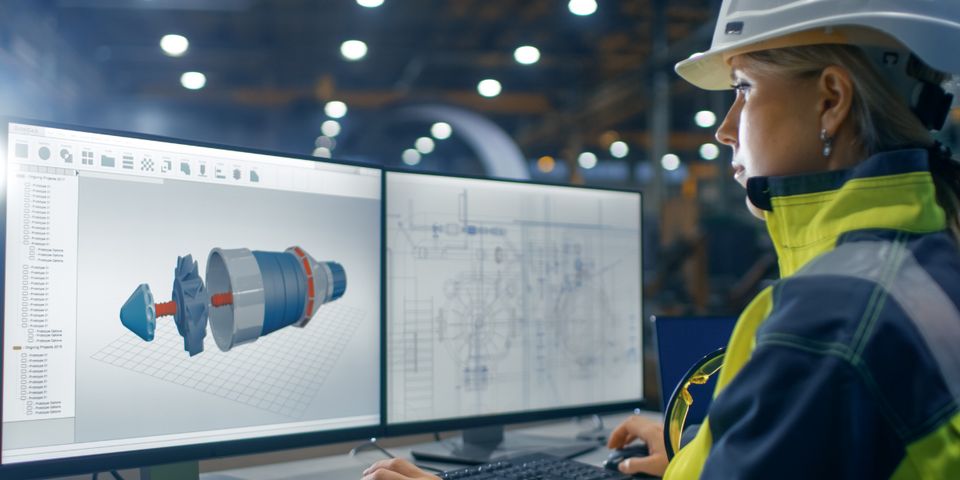

Since the invention of its earliest forms in the 1960s, computer-aided design, or CAD, has been a vital engineering tool. This technology allows technicians and specialists to visualize their projects before they’re completed using 3D models of products, components, and subsystems to evaluate their practicality, function, and features. To understand how it benefits projects from a wide range of fields and industries, have a look at the article below.

What Are the Benefits of CAD in Engineering?

1. Improved Design Quality

CAD software allows engineers to input designs and data to analyze the efficiency and operation of a planned object or device. It can also animate the design to help engineers better visualize a component’s operation. Designers, therefore, have the ability to make rapid corrections and modifications to proposed designs in a risk-free, low-cost environment, resulting in functional, high-quality products without costly errors or design flaws.

2. Laying the Foundation for Manufacturing

If you’re designing a device or component for mass production, the initial design work and documentation form the basis of all later fabrication efforts. In the past, this required identifying the final design on paper and including all of the specifications for production, including dimensions, physical parameters, and required or recommended materials, in the finished document.

Computer-aided designs update as you refine them, with obsolete or unnecessary data and details removed as the design progresses. As a result, once the design is finished in CAD software, it can form a ready-made basis for mass production without further preparation.

3. Time Savings

Engineering projects typically include tight timelines in which to get systems and equipment in place or to get products to market. Traditional design techniques often require lengthy periods of testing and assessment to determine what, if any, inefficiencies or flaws are present and to correct and test them again. This leads to a need for large project budgets and increases the risk of a budget overrun if serious setbacks are encountered either in the design or implementation phases.

CAD can minimize or even eliminate this cumbersome step by allowing designers to make corrections to their designs, test their functions, and analyze potential improvements before a product or component is physically manufactured. Once the design is finalized, you can deliver its precise specifications to a fabricator to streamline production, delivery, and installation times.

If you’re interested in taking advantage of the many benefits of CAD software for your next engineering project, get in touch with CDA Engineering in Troy, MI. Serving clients throughout the Detroit area since 1970, these engineers use the latest CAD software to render precise drawings and plans for a wide variety of parts and subsystems. Call (248) 589-3300 to get started, or visit their website for more information.

About the Business

Have a question? Ask the experts!

Send your question