5 Reasons to Use Rapid Prototyping for Product Development

If you work in product design, you know how valuable a physical prototype can be throughout the development process. While many design teams rely on 3D illustrations or DIY modeling, these solutions don’t always deliver the accuracy that’s required to build something reliable. Fortunately, Faro Industries—a leader in the packaging and prototype industry—says rapid prototyping can allow companies to create scale models without having to invest a lot of time or effort.

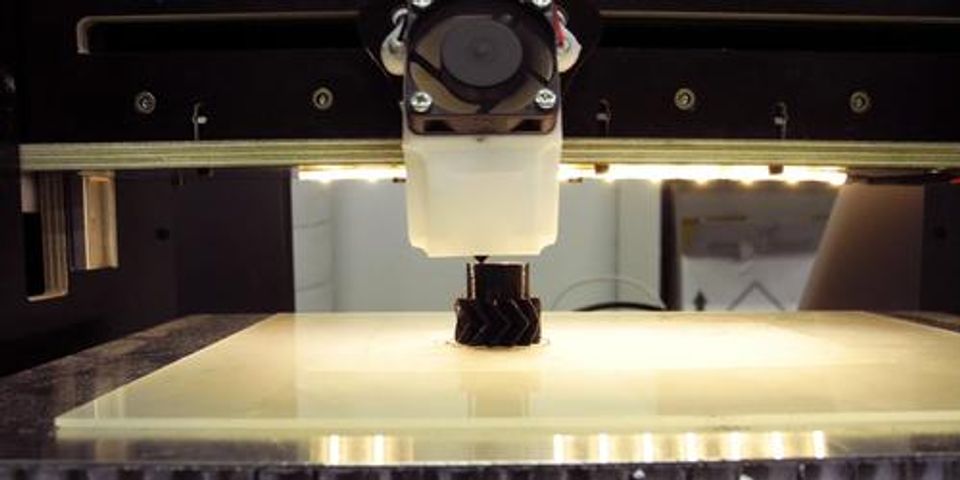

Although rapid prototyping has been around for decades, this global packaging company notes that the advent of 3D printer technology has made the process more accessible and more affordable to businesses. Whether you need a scale model of a new product design or are improving packaging, it’s worth investing in rapid prototyping to:

- Get A Feel For Your Product: As impressive as CAD software is, nothing beats a real live model of the product you design. Rapid prototyping can allow you to turn your CAD imaging into a physical product in a short time, without the need for extensive production runs.

- Reduce Development Time: One of the biggest reasons businesses trust rapid prototyping is its ability to streamline the development process. After the prototype is created, design teams can test the product to eliminate redundancies and mistakes—a process that could take months if done correctly through traditional methods. Changes can be made in real-time through the CAD model and produced, allowing teams to try new things and experiment with fewer restrictions.

Improve Communication: While the design team is at the heart of all prototyping processes, it’s essential to get input from engineering, marketing, purchasing, and other departments. Rapid prototyping allows you to get a tactile product in the hands of these teams, allowing them to remain fully engaged and informed throughout the development process.

Improve Communication: While the design team is at the heart of all prototyping processes, it’s essential to get input from engineering, marketing, purchasing, and other departments. Rapid prototyping allows you to get a tactile product in the hands of these teams, allowing them to remain fully engaged and informed throughout the development process.- Avoid Expensive Mistakes: One slight mishap in sending a CAD design into production can result in big losses for a company, whether the product remains unsatisfactory or has to be recalled. Since rapid prototyping gets models in the hands of development teams early on, problems can be identified before launching an expansive production run.

- Make Variable Products: In the past, prototyping allowed you to make one version of a sample product, while limiting your options for customizing it. With rapid prototyping, you can take a base product and introduce special features to create samples of what an entire product line may look like.

Rapid prototyping is fairly inexpensive when compared to traditional methods and the extensive development time associated with them. To request a quote on your rapid prototyping needs, contact Faro Industries at (585) 647-6000 or visit their website to learn more about this state-of-the-art modeling process.

About the Business

Have a question? Ask the experts!

Send your question