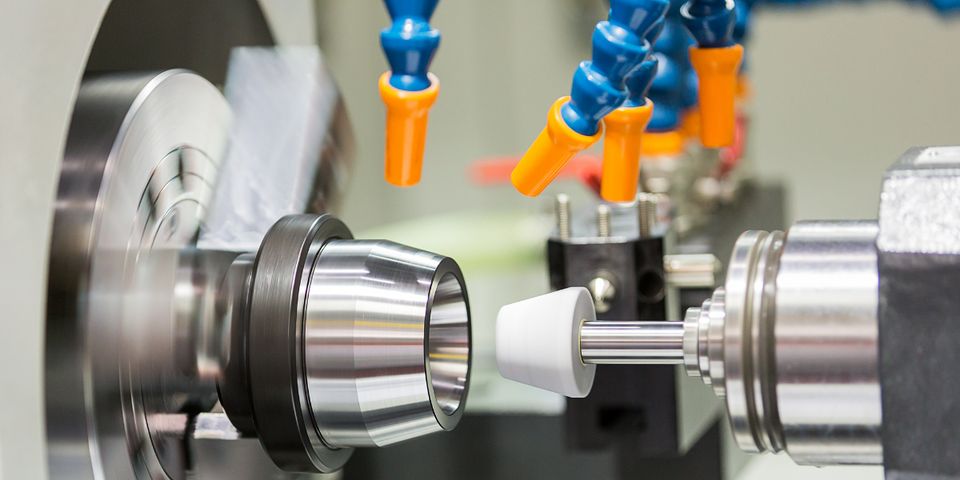

A Guide to CNC Machining Tolerances

If you need custom hardware for your industrial equipment, a CNC machining company should be able to produce it. Short for Computer Numerical Control, CNC makes the automation of precise parts possible using programmable electromechanical devices. Before the CNC machine can manufacture parts that will meet your specifications, though, you're going to have to input each piece's standard tolerance limit. Here's what you should know about how to determine these numbers.

What Is a Standard Tolerance Limit?

When fabricating parts, tolerance refers to the window of deviation that the measurements can have for the parts to still fit properly. Regarding specific parts, the standard tolerance limit is the maximum allowable difference in dimensions before that particular piece of hardware is deemed useless.

Tolerance is measured in inches or millimeters and varies by material. Metal components typically have a limit of +/-0.005 inches, for example, which equates to 0.127 mm. Plastic, on the other hand, has a wider window because it's more malleable. The standard tolerance limit for a plastic part usually falls around +/- 0.01 inches.

What Does It Mean When the Tolerance Is Unilateral?

Tolerance measurements don't always have a minimum and maximum. Some pieces have a unilateral tolerance, meaning the range only extends in one direction. For example, if the part will be inserted into a hole that's 50 mm, the shaft cannot exceed that diameter by even a fraction of a hair.

In such a scenario, the tolerance would be 50 +0.00/-0.05 mm. If you need parts fabricated, you can specify the standard tolerance limit in the drawing, or you can defer to the machining company, which should have a general list of tolerances they can apply.

If you need professionals to produce custom hardware with the correct tolerance limits, turn to Wilson Machine & Welding in Cordova, AL. Having served industrial clients across the Southeastern United States since 1972, this CNC machining company is equipped to work off drawings and reverse engineer parts when drawings aren't available. Their state-of-the-art technology will ensure your facility has the equipment it needs for seamless operations. To discuss your needs, reach out on their website or call (205) 648-3203.

About the Business

Have a question? Ask the experts!

Send your question