Computer Numerical Control (or CNC machining) has been a mainstay of manufacturing and production since the 1940s. Although crude versions of this machinery appeared in the late 19th century, this technique has been perfected throughout the years to become what it is today. Consult the guide below to learn more about CNC machining.

What Is This Type of Machinery?

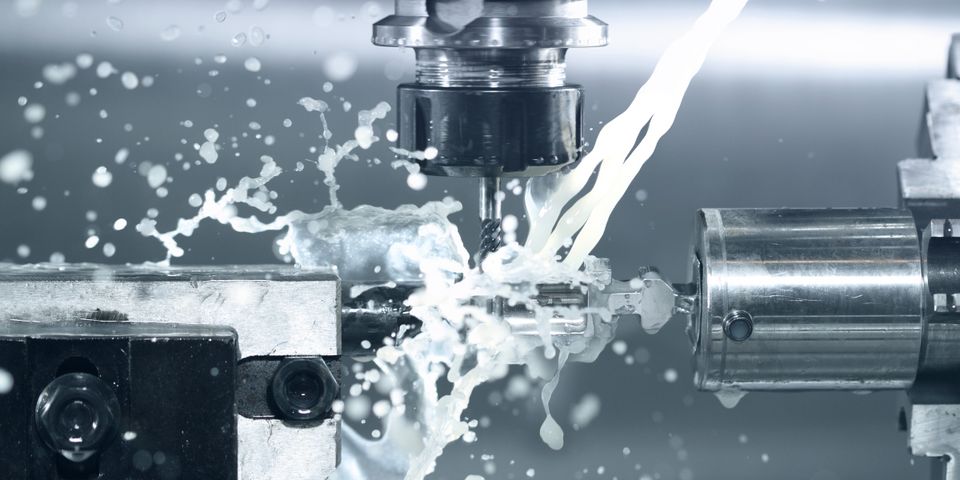

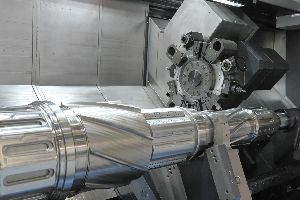

CNC machining combines drills, lathes, and milling tools into cells that the machine can select from and use. Through these tools and a computer program to guide it, a CNC machine will manufacture three-dimensional parts. Advanced CNC machines are able to move along the X, Y, and Z-axis to rotate and flip the component so material can be cut on all sides.

How Did It Originate?

CNC (Computer Numerical Control) machines were predated by turning machines, which originated in 1751. Afterward, the first NC (Numerical Control) was developed by John T. Parsons in 1949. The machine was developed as part of an Air Force research project through MIT. The first machine was built with the goal of producing helicopter blades and stiffer skins for aircraft.

From there, the technology was further developed by Richard Kegg, who, in 1952, released the Cincinnati Hydro-Tel. This prototype operated using paper tape, a tape reader, and an electronic control system and became a focus for future CNC machines. As digital technology emerged in the 1960s and 70s, CNC machining first went to analog computing and then fully digital.

How Is It Used Today?

The primary benefit of CNC machines in modern times is their ability to rapidly and efficiently produce simple or complex parts, especially if there are large quantities of the same part. Thanks to advances in both computing and the capabilities of CNC machines themselves, it is easier than ever to produce parts with minimal need for manual adjustments or intervention. Another benefit is the wide variety of materials that a CNC can work with, from plastics to metals.

The team at Wilson Machine & Welding has proudly served the greater Birmingham & Decatur-Huntsville, Alabama areas, as well as throughout the Southeast, since 1972. Our spacious facilities are staffed with highly skilled machinists, gear-cutters, millwrights, and fabricators who produce a wide range of parts from very large to very small machined components, as well as simple to complicated weldments. We are capable of field machining and fabrication as well as rebuilds in our own shops using CNC and manual machining. For more information, call (205) 648-3203 or visit them online.

About the Business

Have a question? Ask the experts!

Send your question