CNC machining — or computer numerical control machining — is one of the most commonly used fabrication processes today. By pairing machine tools with computer-driven technology, these devices can deliver quality manufacturing results for metals, plastics, wood, and more.

How Does CNC Machining Work?

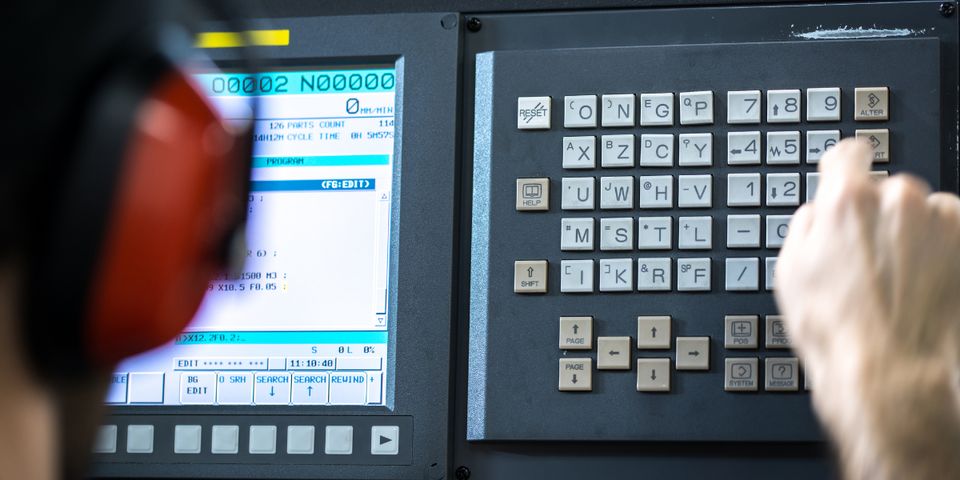

CNC machining makes use of computer-aided drawing (CAD) and computer-aided manufacturing (CAM) software. CAD tools create designs to be used in manufacturing. CAM tools generally work as an add-on to CAD by helping produce cutting simulations and then telling the equipment which cuts to make and where moving parts need to go during the manufacturing process.

Computer controls make it easy for technicians to edit and compare jobs, perform trial runs, or even stop and restart a job if needed. The actual cuts performed by the machine are fully automated, guided by computer software.

What Are Some Common CNC Devices & Applications?

There are several types of CNC machines used today due to ever-improving computer technology. Common machine types include lathes, routers, milling machines, plasma cutters, water jet cutters, turret punchers, and 3D printers. Projects will typically make use of several of these tools to achieve desired specifications.

CNC machines can implement a wide range of tools and components to produce anything from metal auto parts to plastic consumer goods. Because all of the distinct machining components used in manufacturing are controlled via computer coding, users can count on them to deliver quick and accurate results. As long as the programming is accurate, CNC machining will produce high-quality parts as it follows the steps dictated by coding.

From CNC machining to TIG welding, Wilson Machine & Welding in Cordova, AL can help with a wide range of machining and fabricated parts. Serving the region since 1972, their experienced team uses proven techniques and equipment to deliver finished products that will stand the test of time. From repairs to custom-built products, they can do it all. To learn more about their services, visit them online or call (205) 648-3203.

About the Business

Have a question? Ask the experts!

Send your question