What Are the Differences Between Metal Milling & Lathe Machines?

Metal mills and lathes are two types of machining equipment that shape metal and other hard materials into the needed specifications. But they each accomplish this goal in different ways. Below, learn about the differences between mills and lathes and the unique benefits each option offers.

Mills

A metal mill contains a cutting tool, which rotates on its axis to shape a stationary workpiece. The worker feeds the piece into the mill at an angle that matches the axis of the cutting tool. This lets the tool approach the workpiece from a variety of different directions and orientations, which makes it ideal for projects that involve complex or highly detailed parts.

While all metal milling machines work by this same general principle, there are a variety of mills on the market to meet the demands of specific jobs and industries. For instance, both horizontal and vertical mills contain different oriented cutting tools. A CNC machine is a type of computer-controlled mill.

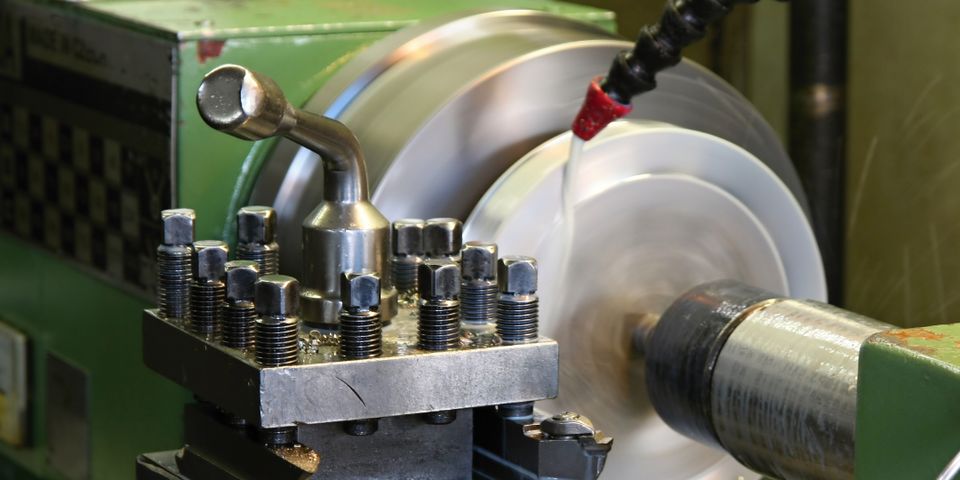

Lathes

With a metal lathe, it is the workpiece that rotates on its axis, not the cutting tool, to create the needed shape. These machines can perform several shaping tasks, including cutting, deforming, drilling, and sanding. Each task utilizes a different tool, which is applied to the workpiece as it rotates. Because the workpiece itself moves, it is held in place with at least one clamp that can be adjusted to accommodate various lengths.

Metal lathes are especially beneficial when shaping cylindrical objects because they maneuver the workpiece around the tool, easily fashioning the items. Common objects made with metal lathes include bowls, pots, and pans; baseball bats and billiard cues; musical instruments; and camshafts.

Wood Machine, Inc., uses both metal mills and lathes in their machining processes. Since 1977, they have been serving customers throughout the Minneapolis/St. Paul, MN, Metro Region. They provide CNC machining, assembling, welding, and fabricating services, and they will handle every step of the design and manufacturing processes, from prototype to production. Call (651) 423-2719 or visit them online to request an estimate for your project.

About the Business

Have a question? Ask the experts!

Send your question