CNC machining provides precise automation for manufacturing throughout a variety of industries. It also offers benefits over manual machines, leading to more efficient, detailed results. Below are a few questions about CNC machines answered.

FAQ About CNC Machines

What is CNC machining?

CNC stands for computer numerical control and consists of computer-automated tools pre-programmed into a sequence of machine commands. Software is used to create parts for manufacturing projects, resulting in high quality, precise designs.

CNC machines typically rely on computer-aided design (CAD) and computer-aided manufacturing (CAM) software to translate plans into results. The computer coding is transformed into electrical signals that control the machine, so it knows when, how, and where to cut.

Which industries use CNC machines?

CNC machines are typically found in an array of industries. The medical community uses this technology to create customized devices for patients, such as implants and medical instruments as well as MRI machines and sterility packaging.

The aerospace industry utilizes these machines to ensure components for aircrafts fit perfectly for optimal function, like landing gear and electrical connectors. CNC machinery can also be beneficial to transportation, such as vital parts for engines and small components, like pins, to build various vehicles.

What types of CNC machines are there?

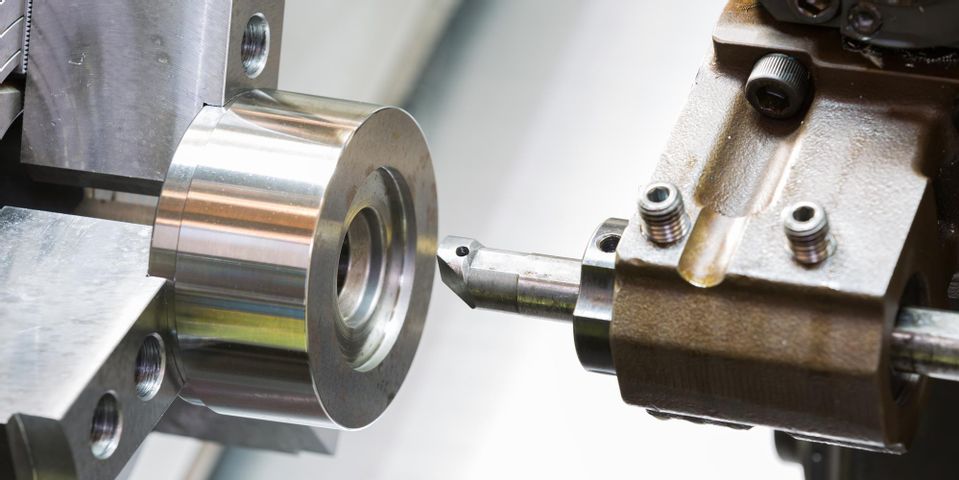

Options include turning, milling, and lathes, among others. Turning machines consist of bars of material that are held and rotated while another tool works to create a specified shape.

Options include turning, milling, and lathes, among others. Turning machines consist of bars of material that are held and rotated while another tool works to create a specified shape.

Milling refers to a process similar to drilling and cutting where a cylindrical tool rotates in different directions along multiple axes to form shapes, holes, slots, and other impressions on the material.

Similar to a conventional lathe, the material is turned against different cutting tools to form a shape. CNC lathes can shear metal and even make plane surfaces and screw threads. There are also ornamental versions for more complicated designs.

What is the importance of CNC?

The biggest reason to use CNC machines is efficiency and precision. Because it is automated by computers, there is less room for error and the time it takes to manufacture components is much less than traditional methods.

It also surpasses partially automated machinery that features manual controls like levers pulled and controlled by trained operators.

When you need CNC machines and metal fabrication in Minneapolis and St. Paul, MN, call Wood Machine. The machine shop offers a list of services for both individuals and businesses seeking welding and metal needs. Their expert team and precise approach ensure a satisfactory result for your project. Call (651) 423-2719 for an estimate or visit them online for their shop’s capabilities.

About the Business

Have a question? Ask the experts!

Send your question